HOME | DD

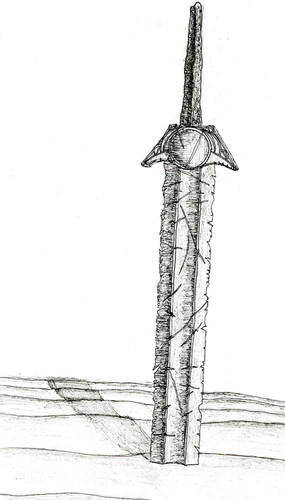

Apothacer — Harmony

Apothacer — Harmony

Published: 2005-06-14 00:53:35 +0000 UTC; Views: 400; Favourites: 4; Downloads: 45

Redirect to original

Description

The peice has a nice flow to it. Hophornbeam handle, saw steel blade, total length about five and one half inches.Related content

Comments: 19

o well done so cool

why dont u work on the wood ? u can do some craving on it it will make much more beatiful

i really like this stuff

👍: 0 ⏩: 1

Hmm... That is a nice idea but the blade is not made of the best metal, it has begun to rust. The other thing I like about the knife is it's simplicity. Prehaps I can carve the handle of the next knife I make.

👍: 0 ⏩: 1

well if want to do some think simple with wood u must find a beatiful wood [ im mean about the color cause u know all of the woods are beatiful some thing like walnut or ....... it looks more pretty if u change ur wood [handle but its really beautiful and different well done

👍: 0 ⏩: 1

I used hornbeam because it is the strongest wood in our forest.

👍: 0 ⏩: 0

Wow... Very nice my friend! It's a very interesting design, and I think it's great!

👍: 0 ⏩: 1

Thanks, I just wish the flute was better, thanks for the

👍: 0 ⏩: 0

Wow, cool! Wish I could make stuff like that.....

👍: 0 ⏩: 1

It's not so hard, look at my knife tutorial.

👍: 0 ⏩: 0

Several questions: about how long have you been making knives?

Do you happen to have a dremmel tool, or some other rotary-shaft tool? What do you use to grind the blade to shape -angle grinder; belt grinder; wheel grinder... file? What is your heat-source -do you use a forge (propane or coal/charcoal?), an oxy-acytelene torch, a kiln?

About... six years ago (jeez, has it been that long?) my knives looked similar to that. Sometime in between, I learned a few simple "tricks" -mostly orders of procedure and ways of thinking, really- that have improved my projects' quality immensely. If I knew what kind of shop you had to work with, I could offer some specific pointers that might be of use.

👍: 0 ⏩: 1

Beleive me I would love a dremmel tool, Thats stamped on with blunted cold chisel, and although it ain't pretty it is my first flut ever and ads stifness since I put tpw otherflutes on the otherside. I used no heat and put my faith in the maufactures of the saw. This knife is an excuse to pound more than anything. anyway I have on hand:

Old saws, old files and rasps, a wood fire furnace that can get steel up to welding heat for (white throwing sparks) for about 3 weeks every spring, a stupendus cold chisel that I was blesed with by god of beginers luck heat treats, files for metal working, an angle grinder, 3 lb hammer, various ball pin hamers, a propane tourch, a propane kitchen stove, a tourmeck combination grinding and honing wheel, metal vise/anvil, a love of steel. I really would not like to be judges by two hours work when trying new operations comong down with a cold, and sweating till the goggles fog. This is phase two of my knifemaking enterprise. Phase one was becoming interested when I had the heat on hand during the winter of aught three. I lost interest after about two months of intense steel uphoria. Phase tow has been a recent rekindling and expansion of knowledge by my high school metals calss. I got a 100% average for every term and that was a LOT of bookwork. I got to learn that I am a natural at MIG welding so much so that the teacher though I was trying to play some trick on him by feigning being a beginer adn producing provesional welds. He wen't and talked to the local employers in our town! I also got an honoraty whosiwhatzit for my "understanding of concepts..." or something along those lines. He may be giving me his anvil that's to big for his needs, from his HOUSE!

👍: 0 ⏩: 1

Cold smithing, in general, is a bad idea. Smashing hard crysteline structures weakens them and can cause micro-fractures that can later lead to major fractures. At *this* size, I'm not at all concerned for your safety -you should be just fine, and I expect the knife will last a good while. It *is* something to keep in mind if you ever want to try a longer knife or a sword, however.

You can do a fuller with your angle-grinder and a metal CUTTING disk (not grinding -you can tell the difference from the bottom... but I suppose you knew that). Do this BEFORE you form the edge. If you have a flat, straight piece, you might even want to do it before you form the profile. Clamp the piece down well, and run the cutting disk vertically along the blade blank. Be careful, and take very small bites. Personally, I suggest running the fuller into the tang, it makes the blade look cleaner. You can clean up the fuller with a "flapper" disk.

Being a welder -as you can tell from my page- REALLY comes in handy. Just look at the Walking Axe to see what I mean. However, I STRONGLY that you learn to weld Stick as well as humanly possible. Reason being, you can find out the steel you've got and what kinds of filler metals work with it, and buy $30 worth of specialty rods at a welding shop and get your projects done. If you try buying just #5 of MIG wire, though, it'll run you $300!!! 0_0 TIG is even better, as you can use a piece of the base metal as your filler material -ditto with Oxy-Acetylene welding (althought it's finiky on high-carbon steels), but those aren't often avalable when you need to get the job done. Stick (SMAW) usually is. Hey, if you learn to weld with a coathanger (it's not exactly easy...), you can use stick to do the same thing. I did once, but the little AC welder I get to use now can't handle it. ....That and I'm out of practice. XD

"forge thick, grind thin."

That's an old piece of bladesmith's wisdom that's just as true today. In stock removal, especially for those of us using angle grinders, grind thick!!! That's our equivalent of forging, and it's just as "rough" as straight from the hammer. Go over your work with a flapper wheel to remove coarse grinding marks -you'll be glad you left yourself some room. When you go on to a finer finish, you'll go over that with a file -and again, you'll be glad. And after that, you can polish and shape the steel with a sharpening stone, or progressively finer grades of sandpaper.

DO NOT try to finish the shape in the rough grind. I know how hard it is to resist the temptation, but believe me, the improvement is worth the effort.

Handle-making. I'm assuming you're using epoxy to fix your handles to the tangs, so far. That's good, it's a strong way to go. However, you might like to try putting hilts on your knives sometime soon -bolsters, butt-caps, real pommels, etc. In that case, you'll have to make those pieces at the same time that you're making your knife, and make them all fit together before you start on the wooden "handle". In that case, it will be to your benefit to make the tang as precicely as possible, so you can either a) take a woodworking chisel and make "slabs" to fit around and cover up the tang, or b) drill out a blank and burn the tang in and later carve the blank to the shape you want.

This can turn into a very time-consuming hobby, you know?

👍: 0 ⏩: 1

Wow, Biggest comment ever. Thanks for the info. I don't have acces to welding equipment anymore, or money. I really won't have any more time doo do metalwork as of yesterday and I won't be able to again till the endo of eh summer. Thanks for the sage advice. What's Stick welding? Our text books are older than I am and the equipment is even older.

👍: 0 ⏩: 1

um... stick welding? Shielded Metal Arc Welding? You know... with the welding rod and the clamps? [link]

👍: 0 ⏩: 1

Oh, yeah I know that, just I thout it was called MIG, Metal Inert Gas? My prowes is mostly that of a steady hand. I should post my first arc weld. *scampers off*

👍: 0 ⏩: 0