HOME | DD

Logan-Pearce — Tutorial 2. Step 3: Tempering

Logan-Pearce — Tutorial 2. Step 3: Tempering

Published: 2011-10-19 17:07:11 +0000 UTC; Views: 11005; Favourites: 17; Downloads: 73

Redirect to original

Description

Previous Step: [link]Step 3: Tempering

Tempering or Drawing Back a knife is taking away some of the the brittleness that comes with hardening. It also takes away some of the hardeness as well. Which means you can actually take away too much hardness and have to reharden and temper the knife, if you don't do this correctly.

The only thing we really need is an oven that will reach 475F degrees. So a mini oven or the one in your kitchen do fine.

What we are trying to do is get the best edge possible with the most flexibility. The more flexibility the less hard the knife is meaning the edge won't last as long. The more brittle and hard the knife is the longer the edge will last, but also the more chance of it breaking or cracking because it is so hard if it is put in a bind. This is why we try to find a good medium point for the knife.

As always it does depend on what type of knife we are making. So first we have to decide what type of knife we are making. If it's a hunter and fighting knives then we usually want the knife to be a little harder than normal knives, but nothing extreme. Most hunting knives and fighters will be used for their cutting edge and most likely won't be put into any extreme stressful situations. For these you can temper at a lower degree of heat. Something like 300-350F. This will make the steel a bright yellow for carbon based steels.

Bowies and utility blades we usually go higher, because they will be used to chop and most likely be forced to do things knives aren't meant to be used for. Somewhere around 400-450F is good. It gives the blade a lot more flexibility while not compromising the cutting edge to much.

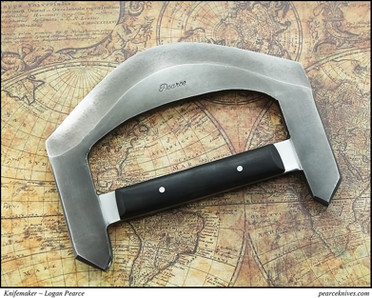

Swords, cleavers, and axes go around 425-475. It's not a lot higher than the other, but if gives more flexibility to the blades. With axes it will reduce the amount of chipping with nix in the blade, which are usually a lot easier to get out than a chip. It's basically the same for a sword, because of the shock resistance as well. Sharpening is usually a little easier at this range as well, which for meat cleavers and axes is something that is done relatively often, depending on how much it is used.

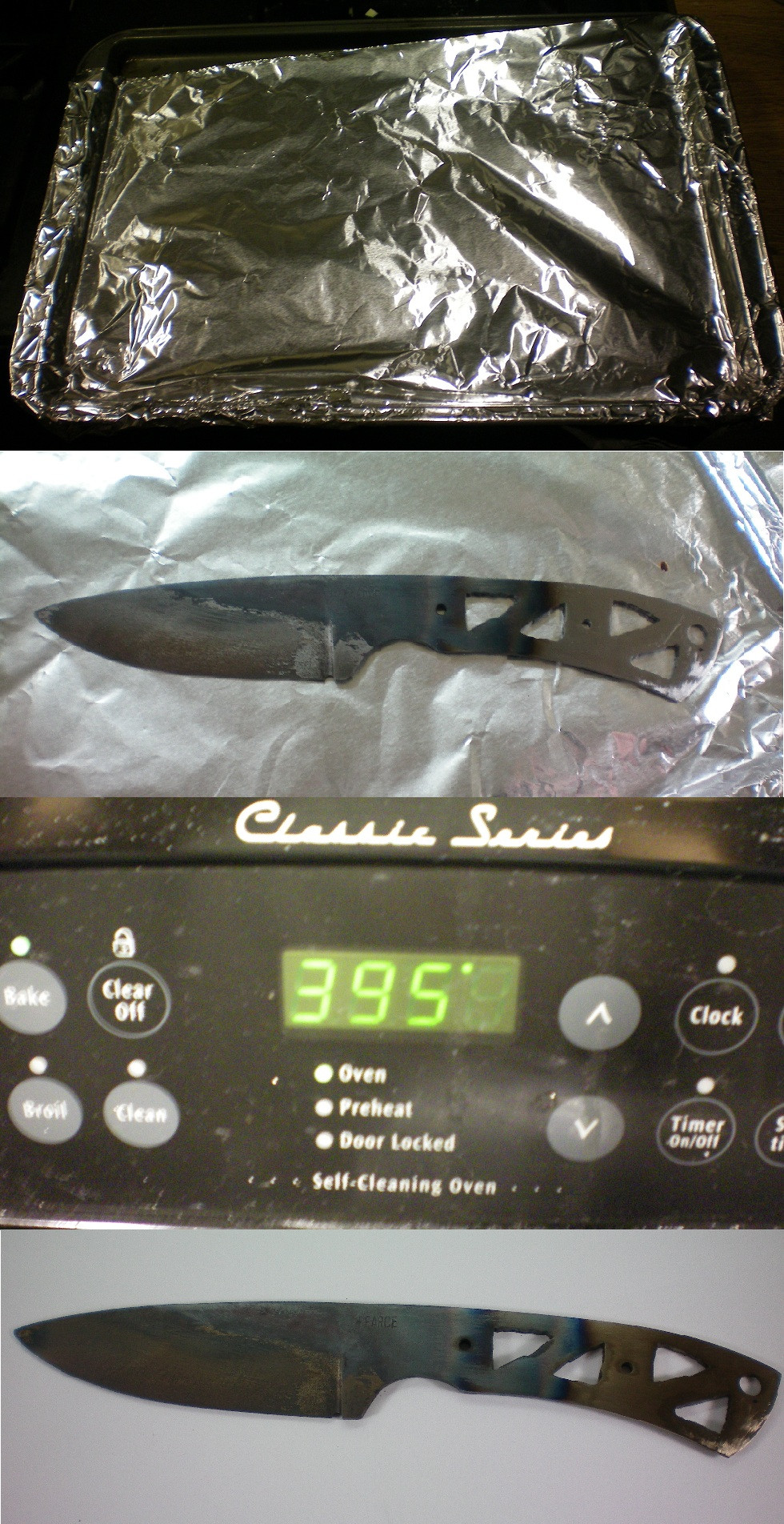

Before we start tempering the knife, it would be wise to clean up the knife. It isn't needed, but if you are just starting to do this or it is a new type of metal for you, then getting the blade back to 120 grit would be a good idea. Since I've done this a few times, I don't really have to worry about it too much, but I do always keep the end of my tapered tang cleaned up. Since the whole knife is going to be in the oven and the end of my tang is about the same thickness as my blade, I can just watch the tang's color as indication. I'm shooting for a yellow color. More of a straw yellow since I'm heat treating at 400F. Again this is because it is 1080, but 400F should get any carbon metal that has 60 points or higher to this yellow color.

Since this is a utility knife and I don't know for sure what it will be used for. I hit the mid range temper for this knife. To give it as much balance as possible. This is a small bladed knife, so I'm going to keep it closer to the hardness rather than flexibility of the mid range point. Since I'm doing that I pre-heat my oven to 395 and then I get my pan that I'm using to set the knife on. You don't have to use a pan, but I like to and usually, as you can see in the picture, I cover it with tin foil since I haven't really cleaned the knife up yet.

I like to do a triple temper, so just like normalizing and hardening, I will be doing the cycle three times. Since I'm trying to keep this knife a little hard, I'm only going to do each cycle for one hour each time.

Once the oven is ready, I place the knife in the oven for an hour. If you are going for a more flexible blade then you can do it for two hours each cycle.

Once the hour is up, I pull the knife out and let it cool down to room temperature. Once it's cooled down then I put it back in for another cycle.

After the third and final cycle it should be the color your were shooting for. Its a little hard to see, but even where why quench blew off the heat scales, it has turned yellowish. This is a good sign.

You can check the final results of your work with a few ways. A file is one way to go. You can run the file over the knife when you harden it and if it doesn't bite into it, then it's hardened and then again after tempering with close to the same effect, except you want it to bit in some. It's not the method I recommend, but some people do it that way.

You can also use the brass rod test. Which is basically taking a brass rod and running the edge over it. You'll need to flex your edge over the brass rod. One of three things will happen:

1) You're edge will chip. Which means your blade is hard as hell and most likely to hard for anything you are wanting. You'll have to fix that chip and then temper the blade again.

2) The edge will roll over. Your blade is to soft. You need to reharden and temper the blade.

3) The blade will flex back into place when you pull away from the rod. This is what you are wanting. A balance between hard and soft.

If you are trying for a hard blade which you know won't be under any stress than a small amount of chipping is okay. But it would need to be very small.

I have seen people continue to use this method on the same knife that was just too hard and he basically ruined the knife because he never tempered it right and didn't have enough metal to continue.

There are also companies that will test the HRC of your knife for you as well as an HRC machine that can be bought or made. All of that is on a whole other level of information though.

This is the last step of heat treating. Once my triple temper is done, I clean up the blade and get it ready to be handled.

Blade Antiquing: [link]

You should seeeeee the knives I finished this week. <3 Too bad my camera hasn't come in yet.

Logan Pearce

www.pearceknives.com

Facebook-> [link]

Related content

Comments: 15

Does the aluminum foil transfer any of its properties to the metal you are using when you are in the oven?

👍: 0 ⏩: 0

The funny thing is that i just got a super-heated knife in Fallout today.

👍: 0 ⏩: 0

I just work harden my by beating the shit out of it for 6 weeks. no heat no fuss.

👍: 0 ⏩: 2

Yeah! Just beat it a long time with a hammer and it will magically be hardened. I like that plan.

👍: 0 ⏩: 0

I love to cook..... cooking knives though.... thats new

👍: 0 ⏩: 0

With 1095 I go to 425 F.

I now know what to do with 1080

👍: 0 ⏩: 1

425-450 is good for 1090s for ease of sharpening/flexibility without loosing enough of the hardness/edge to comprise the knife. Most of the 10XX series are the same. You could do 1080 the same way, but I want the edge to last longer, so I'm sacrificing the flexibility for that.

👍: 0 ⏩: 1

PSSSSSHHHH!!!!! THATS THE FANCY WAY TO DO IT!!!! I USE A BUCKET OF WATER AND A FILE!!!!

👍: 0 ⏩: 0

Ahh, the venerable toaster oven. I picked one of these up just after i started making knives. I used to use a torch on the spine before i got my edge quenching down pat, but now there is no need. Also, Lazy means one can get on with making more knives.

👍: 0 ⏩: 1

Right on! Plus it allows me to temper more than one knife at a time. Just makes life easier all the way around, even if it does take longer.

👍: 0 ⏩: 0

Very nice! How do you feel about tempering with a gas flame on the stove top?

👍: 0 ⏩: 1

I wouldn't do it that way, but if the temperature and exposure time was right, then it could be done. The oven is just the laziest way for me.

👍: 0 ⏩: 1

Just because it's lazy doesn't mean it isn't effective

👍: 0 ⏩: 0